What Is an Industrial Autoclave?

An industrial autoclave is a sealed pressure vessel used for sterilising and pasteurising food with steam at high pressure and controlled temperature. This thermal treatment eliminates microorganisms responsible for spoilage, ensuring long-term product stability without compromising quality, taste, or texture.

How It Works

The operation of an autoclave is similar to that of a steam boiler. Products — packed in jars, cans, or flexible pouches — are placed inside the chamber, which is then hermetically sealed. Steam is introduced under high pressure, raising the internal temperature to the required level.

This combination of temperature, pressure, and exposure time guarantees effective sterilisation and uniform heat distribution throughout the load.

Applications in the Food Industry

Industrial autoclaves are used across multiple food segments, including:

- Canned foods: sterilisation of meat, fish, vegetables, soups, sauces, and ready meals.

- Dairy and beverages: pasteurisation of milk, juices, yoghurts, and plant-based drinks.

- Meat products: cooking and sterilising sausages, pâtés, and spreads.

- Ready-to-eat meals: sous-vide and vacuum-packed dishes for retail or food service.

(Although similar technology is used in the medical field, the design and process parameters differ.)

Key Advantages of Industrial Autoclaves

- Extended shelf life: eliminates bacteria and spores, allowing safe long-term storage.

- Preserved taste and texture: modern autoclaves enable precise control of temperature and pressure, maintaining product quality.

- High throughput: capable of processing large batches or continuous loads efficiently.

- Energy efficiency and safety: advanced models integrate heat recovery systems and multiple safety protections.

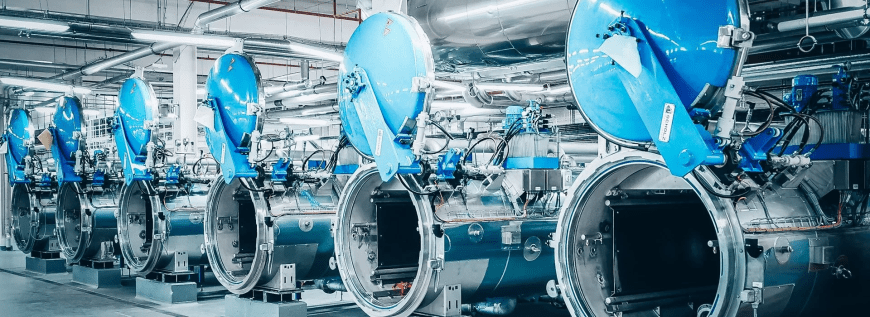

Types of Industrial Autoclaves

Different autoclave designs suit various production needs:

- Horizontal autoclaves – the most common configuration, ideal for high-capacity operations.

- Vertical autoclaves – compact solutions for smaller facilities or pilot lines.

- Rotary autoclaves – provide gentle, continuous agitation of containers for uniform heating and reduced processing time.

How to Choose the Right Autoclave

When selecting an autoclave for your production line, consider:

- The type and packaging of your products.

- The required throughput and cycle time.

- The available space and integration with existing lines.

- Your budget and expected energy efficiency.

Consulting an experienced supplier will help you identify the most suitable configuration for your application — whether for traditional canning or modern ready-meal production.

Conclusion

An industrial autoclave is a cornerstone of modern food manufacturing. It ensures microbiological safety, extends shelf life, and maintains the natural quality of products.

For companies aiming to optimise efficiency and guarantee consistent results, investing in the right autoclave solution is essential — and should always be done in partnership with qualified process engineers and equipment experts.