Ceramic Reflectors for PET Bottle Manufacturing: Energy-Efficient Technology for MENA Region Blow Molding Operations

Introduction: Energy-Efficient PET Bottle Production Technology

The Middle East and North Africa (MENA) region faces unprecedented challenges in PET bottle manufacturing. With energy costs representing up to 40% of total production expenses in blow molding operations, manufacturers urgently need energy-efficient solutions. Ceramic reflector technology offers a revolutionary approach to preform heating, delivering significant energy savings and quality improvements for bottle production lines.

The global packaging industry, valued at over $1 trillion in 2024, demands innovative manufacturing solutions. MENA manufacturers face rising energy costs, stricter environmental regulations, and increasing quality requirements – challenges that ceramic reflector systems directly address.

Ceramic Reflector Technology: Advanced Infrared Heating for Blow Molding

How Ceramic Reflectors Work in PET Bottle Manufacturing

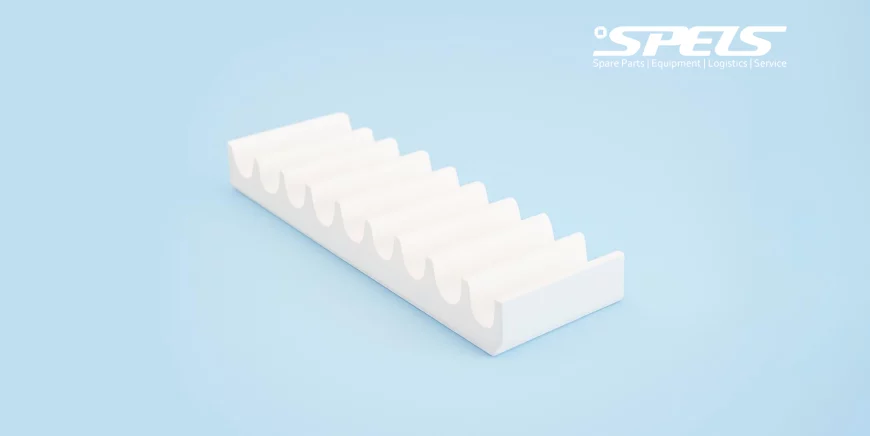

Ceramic reflectors utilize specialized high-temperature ceramic materials with elevated aluminum oxide concentrations, achieving infrared reflectivity coefficients exceeding 90% in the critical 2-5 micrometer range. The parabolic wave design creates multiple focal points that distribute infrared energy uniformly across preforms, eliminating hot spots and shadow zones common in traditional aluminum systems.

Key Advantages Over Aluminum Reflectors

Superior Energy Efficiency: Ceramics deliver up to 25% better energy transfer efficiency compared to aluminum reflectors in blow molding applications.

Temperature Stability: Ceramic materials maintain reflective properties at temperatures exceeding 400°C, while aluminum degrades at lower temperatures.

Self-Cleaning Properties: At operating temperatures of 300-400°C, ceramic surfaces thermally decompose contaminants, eliminating manual cleaning requirements.

Proven Energy Savings and Production Benefits

Quantified Energy Reduction Results

Independent testing demonstrates consistent energy savings of 15-30% with ceramic reflector systems:

- Daily electricity savings: 150-300 kWh per 50,000 bottle production cycle

- Annual energy cost reduction: $15,000-30,000 (based on $0.12/kWh MENA industrial rates)

- Carbon footprint reduction: 75-150 tons CO2 equivalent annually

- Large facility savings: $180,000-360,000 annually for 18 million bottle production

Production Efficiency Improvements

Temperature Control Enhancement:

- Neck temperature reduction: 9.4°C average decrease (46.7°C to 37.3°C)

- Temperature uniformity improvement: 40-60% standard deviation reduction

- Heating cycle optimization: 12-18% reduction in preform heating time

Production Optimization Options:

- Increased throughput: 15-20% more preforms per heating cycle

- Faster cycle times: 12-18% reduction in heating duration

- Enhanced quality: 25-35% reduction in thickness variation defects

Quality Improvements: Preventing Bottle Neck Deformation

Precision Heating for Better Bottle Quality

Ceramic reflectors’ precise parabolic geometry focuses infrared energy exclusively on bottle bodies, preventing neck finish deformation common with aluminum systems. This precision heating prevents:

- Thread distortion affecting cap sealing

- Dimensional variations impacting filling line compatibility

- Surface irregularities affecting product appearance

Measured Quality Enhancements

Production facilities using ceramic reflectors report:

- Neck finish precision: 60-75% reduction in out-of-specification parts

- Wall thickness uniformity: 35-45% improvement

- Reject rate reduction: 40-55% decrease in quality-related waste

- Customer complaints: 70-80% reduction in packaging issues

MENA Region Economic Factors

Industrial electricity rates have increased 20-40% across MENA since 2020 due to energy subsidy reforms, making energy-efficient technologies increasingly valuable for manufacturing competitiveness.

Implementation: Modular Design for Flexible Upgrades

Independent Panel System Benefits

Maintenance Efficiency: Individual panel replacement reduces maintenance windows from 4-6 hours to 30-45 minutes Scalability: Phased implementation aligned with production schedules and budgets Reliability: System redundancy ensures continued operation during panel maintenance

Phased Implementation Strategy

Phase 1: Pilot installation on single production line for performance validation Phase 2: Gradual expansion to additional lines based on priorities Phase 3: Complete facility upgrade with optimized maintenance schedules

Environmental Impact: Sustainable Manufacturing Solutions

Carbon Footprint Reduction

Ceramic reflector technology supports MENA sustainability initiatives through:

- Direct energy savings: 15-30% reduction in heating energy consumption

- Waste reduction: Improved quality control reduces material waste

- Equipment longevity: Reduced thermal stress extends heating system lifespan

How Spels Delivers Ceramic Reflector Solutions

Comprehensive Technology Solutions

Spels provides complete ceramic reflector implementation for MENA manufacturers:

Technical Assessment: Detailed analysis of existing heating systems to quantify potential benefits and optimization opportunities.

Custom Engineering: Tailored ceramic reflector solutions designed for specific bottle types, production volumes, and quality requirements.

Installation & Commissioning: Complete project management from design through production validation and operator training.

Ongoing Support: Maintenance programs, spare parts availability, and continuous performance optimization.

Proven Results Across MENA Region

Spels has successfully implemented ceramic reflector upgrades delivering:

- Energy savings consistently exceeding projections

- Quality improvements reducing customer complaints

- Reliable operation with minimal maintenance requirements

- Technical support ensuring long-term success

Investment Support Services

Performance Guarantees: Guaranteed energy savings and quality improvements backed by comprehensive warranties Flexible Financing: Payment structures aligned with realized savings to minimize financial impact Training Programs: Comprehensive operator and maintenance training for optimal system performance

Future Technology Trends in Blow Molding

Emerging Innovations

Advanced Materials: New ceramic formulations offering higher reflectivity and thermal stability Smart Controls: IoT integration for real-time performance monitoring and predictive maintenance Energy Recovery: Heat recovery systems maximizing thermal efficiency

Market Drivers in MENA Region

- Sustainability mandates: Corporate commitments driving energy-efficient technology adoption

- Quality requirements: Stringent packaging standards for food and beverage applications

- Economic diversification: Government initiatives promoting manufacturing efficiency improvements

Conclusion: Competitive Advantage Through Advanced Technology

Ceramic reflector technology represents a strategic investment in manufacturing competitiveness for MENA region bottle producers. The technology delivers:

Immediate Benefits:

- 15-30% energy cost reduction

- 40-75% improvement in quality metrics

- 14-20 month payback periods

Long-term Advantages:

- Sustained cost leadership through ongoing energy savings

- Superior product quality meeting international standards

- Enhanced operational reliability and reduced maintenance

Environmental Responsibility:

- Significant carbon footprint reduction

- Compliance with evolving sustainability regulations

- Support for corporate environmental commitments

As energy costs continue rising and quality requirements intensify, MENA manufacturers adopting ceramic reflector technology establish competitive advantages that become increasingly difficult for competitors to match.

Transform Your Production with Spels Ceramic Reflector Technology

Ready to optimize your PET bottle production? Contact Spels today for a comprehensive facility assessment. Discover how ceramic reflector technology can reduce your energy costs by up to 30%, improve bottle quality, and position your operation for sustained success in the competitive MENA packaging market.

Key Benefits Summary:

- ✓ 15-30% energy savings guaranteed

- ✓ Superior bottle quality and consistency

- ✓ 14-20 month ROI payback

- ✓ Reduced maintenance requirements

- ✓ Environmental compliance support

Contact Spels now to schedule your energy efficiency assessment and take the first step toward transforming your blow molding operations with proven ceramic reflector technology.

Contact us

📞 +971 56 955 40 26