Selecting the right pump for food production is a crucial engineering decision that impacts process efficiency, product integrity, and overall operational cost. Each pump type offers unique strengths and limitations, making it essential to understand their characteristics before integrating them into a production line.

Below we explore the four most common pump technologies used in food and beverage applications — screw, diaphragm, lobe, and centrifugal pumps.

Screw Pumps

Operating principle:

Screw pumps transfer fluids through the rotation and interaction of two or more intermeshing screws.

Key benefits:

They deliver a smooth, pulse-free flow and are ideal for viscous products such as sauces, creams, or doughs. Their gentle pumping action preserves the structure of delicate ingredients and reduces shear stress on the product.

Advantages:

- High efficiency and stable flow

- Excellent for viscous or multiphase fluids

- Gentle handling of sensitive products

Limitations:

- Higher initial cost

- Potential screw wear during extended operation

Diaphragm Pumps

Operating principle:

A flexible diaphragm moves back and forth to create suction and discharge, moving the fluid through the chamber.

Applications:

Diaphragm pumps are well suited for chemical dosing, CIP chemicals, and applications where high chemical resistance is required.

Advantages:

- Excellent resistance to aggressive or corrosive media

- Ability to generate high pressure

- Accurate dosing control

Limitations:

- Lower flow capacity

- Membranes require periodic replacement

Lobe Pumps

Operating principle:

Lobe (or rotary lobe) pumps use two synchronized rotors (lobes) to trap and move the product through the pump chamber.

Applications:

Commonly used for dairy products, beverages, sauces, and syrups, where maintaining hygiene and gentle product handling is vital.

Advantages:

- High performance and self-priming capability

- Can handle liquids containing gas or air

- Hygienic design, easy to clean (CIP/SIP compatible)

Limitations:

- Possible flow pulsations

- Wear of lobes over time, especially with abrasive media

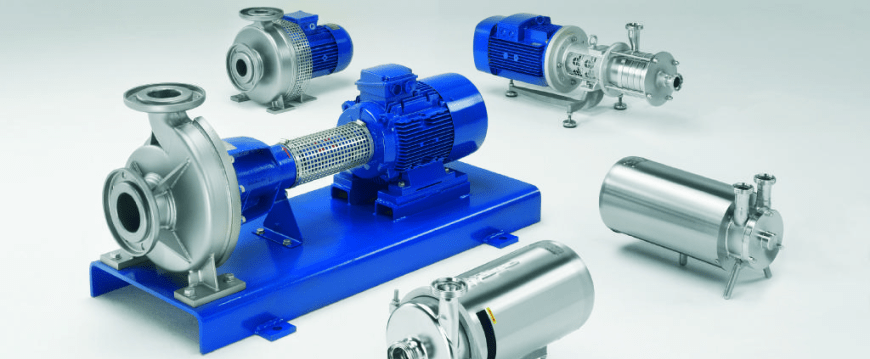

Centrifugal Pumps

Operating principle:

Centrifugal pumps convert the kinetic energy of a rotating impeller into hydraulic energy, efficiently moving low-viscosity liquids.

Applications:

Widely used in water transfer, milk processing, and general liquid circulation due to their simple design and compact dimensions.

Advantages:

- High flow capacity

- Compact and cost-effective

- Easy to maintain and operate

Limitations:

- Inefficient with viscous products

- Not self-priming

Conclusion

Each pump type — screw, diaphragm, lobe, or centrifugal — has its specific role in food processing, depending on viscosity, product sensitivity, and required flow rate.

When designing a food production system, it’s critical to evaluate product characteristics, hygiene requirements, and operating conditions before choosing the right pump.

At SPELS, we help manufacturers select and integrate the most suitable pumping technology for their process — ensuring reliable performance, product quality, and long-term operational efficiency.